After working for five years in the US after completing his education, Arvind Lakshmikumar and his wife decided it was time to come home; and so, in 2004, they did. After a short stint at Honeywell, Lakshmikumar was back then heading technology and operations at the Indian arm of the US-based Sarnoff Corporation, which specialised in vision, video and semiconductor technology innovations. In his stint in the US, he was the director for a number of international military programmes (DARPA, US Army, NSF and DRDO) and lead subcontractor on multiple next-generation military programmes. Lakshmikumar built various imaging systems for Boeing and Lockheed Martin and was part of programmes such as Future Combat Systems, which made the US Army combat-ready for modern warfare. “When we came back to India, we looked at all the companies in the defence sector. They were mostly using screwdriver technology,” explains Lakshmikumar, CEO, Tonbo Imaging. In other words, they were buying products from Europe and the US or Israel and putting them together as there was no ecosystem to build products from the ground up. “There is no harm in buying from companies overseas as long as you have access to the best technology and control over the same. But unfortunately, when you buy this way, you don’t have access to the best technology and every time you face a problem, you have to go back to the seller and are subject to their whims,” adds Lakshmikumar.

This is why Lakshmikumar and his team decided to set up Tonbo Imaging after completing a management buyout of the Indian arm of Sarnoff Corporation, which in turn decided to divest its Indian operations in 2008, giving Tonbo everything except its products, which were protected by IP restrictions. Thomas M Strat, who was a programme manager and assistant director at DARPA — an agency of the US Department of Defence that is responsible for the development of emerging technologies to be used by the military — and is now an advisor to Tonbo, thinks it was a smart move by Lakshmikumar and his team. “Sarnoff had some capable scientists and engineers at its Bengaluru facility. If you are starting a company, there is nothing better than to have top-notch talent working for you. This has been one of the primary reasons for Tonbo’s success.” Explains Lakshmikumar, “We bought out their assets and shares in India but decided to build the products from scratch. We chose defence as our core market because as far as night-vision technology was concerned, Indian defence was lagging behind.”

This is why Lakshmikumar and his team decided to set up Tonbo Imaging after completing a management buyout of the Indian arm of Sarnoff Corporation, which in turn decided to divest its Indian operations in 2008, giving Tonbo everything except its products, which were protected by IP restrictions. Thomas M Strat, who was a programme manager and assistant director at DARPA — an agency of the US Department of Defence that is responsible for the development of emerging technologies to be used by the military — and is now an advisor to Tonbo, thinks it was a smart move by Lakshmikumar and his team. “Sarnoff had some capable scientists and engineers at its Bengaluru facility. If you are starting a company, there is nothing better than to have top-notch talent working for you. This has been one of the primary reasons for Tonbo’s success.” Explains Lakshmikumar, “We bought out their assets and shares in India but decided to build the products from scratch. We chose defence as our core market because as far as night-vision technology was concerned, Indian defence was lagging behind.”

Adding that the country was till then dependent on PSUs and defence labs — which had little incentive to build and commercialise core technology — for such products, Lakshmikumar explains how his company decided to structure itself like a Valley products company. “We decided that our core focus would be cutting-edge night-vision technology for soldiers, land and naval systems, weapons and aerial platforms. Imaging and interpretation strategic electronics technology is what we decided to build.” Tonbo soon realised that it wouldn’t be able to compete with the big guys such as Lockheed Martin or Raytheon by building a similar model. After all, most imaging and military equipment companies are vertically integrated because there was no ecosystem in place when they started out. “These companies had to invest a lot more in infrastructure and technology. Luckily for us, we were able to ride the consumer electronics ecosystem. Today, the electronics that goes into your smartphone is more powerful than what goes into a 155 mm Howitzer gun. So, we leveraged this ecosystem and built solutions for the market. This way, we didn’t have to set up large manufacturing facilities,” explains Lakshmikumar.

Local Muscle

So far, the company has set up a pretty strong supply chain, which has in turn helped it leverage the power of contract manufacturing. “Our model is something like Apple’s, where we control the IP and supply chain, and own the customer. Suppliers must feel that you are the company they should bet on. Everything else is unimportant. By outsourcing the manufacturing process and controlling prices, we can offer competitive rates and still make a 50% gross margin in this business,” Lakshmikumar says. The company has set up a contract manufacturing facility in Kochi and manages to offer products 50% cheaper than its foreign competitors. About 80% of its revenue comes from exports to the US, Europe and Singapore, where it competes with Thales and Sagem, two of the biggest players in this space. “The team at Tonbo Imaging has strong domain expertise, which it has successfully leveraged to build best-in-class products at competitive prices,” says Ramesh Radhakrishnan, partner, Artiman Ventures, which invested in the firm in 2012. “The company is able to leverage innovative designs in micro-optics, low-power electronics and real-time imaging processing to design imaging systems for real-world applications.”

But for the start-up to gets its footing in the Indian defence space, the validation had to come from outside. “Defence is a complex business for a start-up to get into in India. Customers here started adopting our products only after we sold them outside. For us, the objective was to get cracking on a few international sales; the local attitude would change thereafter,” explains Lakshmikumar. He says that traditionally, all military programmes used to either buy global or buy and then make in India, where PSUs such as Bharat Electronics would manufacture products after technology transfers. But all that is now changing, with the defence ministry updating the defence procurement procedures and introducing a new category for locally made products, called indigenously designed developed and manufactured (IDDM) items; these will be a priority during procurement. There are two subcategories within this segment: one that calls for 40% of the content to be sourced locally when the product is designed in India and the second that calls for 60% of the content to be sourced locally when the product is not designed in India.

“So, if there is an Indian manufacturer who indigenously designs, develops and manufactures for a programme, he will be the highest in the food chain. Our products are 95% indigenously built, since the only thing we source from outside are detectors; optics, electronics, software and IP are all built by us. This allows us to sit with the big boys at the table,” he says. Apart from being prime bidders, Tonbo also works with larger players such as L&T, Bharat Electronics, Norway’s Kongsberg (which makes the largest remote-controlled weapons platform) and Greece’s Hellenic Systems (which supplies Howitzer guns to Indian defence). IDDM allows Tonbo to move from smaller projects to building for larger, $500-million contracts. But winning contracts is one thing — execution is a whole another deal. So, the company is now looking to raise its next round of funding of around $30 million-50 million and is in talks with several investors.

Its first infusion had come in the form of angel funding from Mumbai Angels in 2011. “We were the first investors in the company. What impressed me back then was the fact even at that early stage, the team was very professional,” says Anand Ladsariya, angel investor and a member of the Mumbai Angels. “They had domain expertise and innovation was their strength, but the key was that they were able to articulate their vision about how they would leverage that innovation to build a successful commercial business. A lot of start-ups fail when they make the transition from concept to commercialisation, but Tonbo had it all figured out.” Ladsariya rates Tonbo as one of the top three investments of the 80-odd he has made so far. Tonbo followed the angel round of funding with its first institutional round of funding from Artiman Ventures in 2012. “We met in 2011 and were very impressed by the team at Tonbo and the products they were building. We waited for a year to see some traction before we invested. We are excited to be a part of the growth story of a world-class company like Tonbo,” says Radhakrishnan.

Night vision, by day

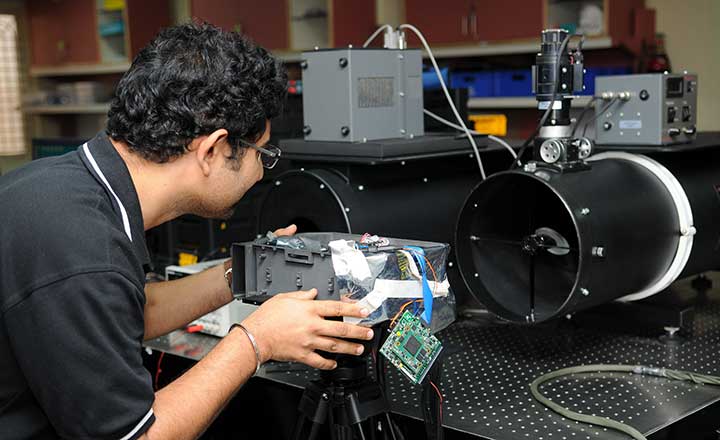

Among the other ideas the founders were sure about was the conviction that the company wouldn’t make India-centric products but those that would find a place in the global market. Tonbo builds advanced imaging and sensor systems that allow soldiers to see during night and day and through dense smoke, dust, fog and foliage. This is possible through the use of fusion technology that combines thermal and visual images into a single video feed, giving soldiers a real-time interpretation of the battlefield. For instance, its enhanced vehicle imaging platform provides a comprehensive 360-degree view of the landscape to the driver and his crew during all weather conditions. “The imaging systems that go on top of guns, UAVs or into weapons systems are actually cameras in some form or the other. For years, the design process for cameras has not changed: it still includes a single sensor, a single lens and an electronics package. But in nature, be it humans or insects, all creatures have multiple eyes that help us see the environment better. So, we decided to incorporate multiple apertures while designing our imaging systems,” he explains. In fact, Tonbo means dragonfly in Japanese, and dragonflies are known to have 40,000 eyes, the compound structure of which allows them to sense things in really low-light conditions even at lightning speeds.

“We develop the product according to the application. For instance, if a solider wants to see long-range in a battlefield or you have to put a camera on a UAV, you have to correct for turbulence. Then, we change the lens design, use consumer electronics for processing and thus create a powerful imaging system. We are the only ones to build night-vision platforms of this sort and this allows us to build very low-cost night-vision equipment,” says the proud founder. No wonder, then, that it is the only Indian company on every electro-optics and night-vision programme of the Indian MoD. Apart from being part of the Indian navy’s modernisation program, Tonbo, which has an order book of $50 million executable over the next 18 months, is also the electro-optics supplier of choice in the Indian army’s $10-billion future infantry combat vehicle programme.

“We started working with Tonbo in 2011. We supply thermal sensors to OEMs, who then system integrate it into the cameras or imaging systems and supply that to their military clients. In India, we have worked with eight to 10 OEMs and found Tonbo to be the best. The company is very quick when it comes to product development,” says Mridul Sharma, national manager, special product group, AIMIL, which develops Indian OEMs for French company ULIS, the second largest manufacturer of uncooled infrared detectors in the world. “The company has been able to successfully compete with global players with lesser resources in terms of capital in an intensely competitive market. You have to be extremely smart to do that.” Customers vouch for those smarts, too. “I have worked with Arvind in the past, when I was serving as a commander with NATO, and later as a customer for Tonbo’s surveillance systems. He has built an enviable repertoire of imaging systems addressing guns, tanks and missiles,” says General Lucas Arnold, chairman of US security firm Chevronstar.

The company has 85 engineers on its core technology team and another 15 in sales and marketing. While Tonbo has thus far managed to retain most of its talent, it couldn’t hold back one of its earliest recruits Binny Bansal, who joined the company straight out of IIT and went on to start Flipkart with his college mate. “He was a regular nerd who did coding before he left us. We wonder if he was the smart one: look at where he is and where we are,” laughs Lakshmikumar. He adds that the only way to scale a business is by hiring people smarter than yourself, and to his credit, he does seem to have an eye for spotting good talent. “Leadership is critically important to keep a start-up going because starting a business is tough. Arvind has the right balance of technical chops and leadership abilities. He has lined up investments and landed contracts while retaining top-notch talent,” says Strat. Apart from building cutting-edge products and platforms for the defence sector, the company is also looking at sectors such as transportation and consumer IoT, where its products can be leveraged.

Tonbo is also working on technologies that it can leverage in the coming decade. “We are working on a pilot project with Tesla to see how night-vision technology can be integrated seamlessly with display,” reveals Lakshmikumar. Little wonder, he has big plans for Tonbo Imaging. “We want to make Tonbo the single largest electro-optics firm in the world. We want to control the algorithms, the platforms and the customers.” In doing so, Tonbo is looking at a multifold increase in revenue, in turn, giving the start-up a pop in its valuation. Lakshmikumar, though, sounds modest. “Valuation is in the eye of the beholder. All we want to create is a business with intrinsic value,” he smiles.